-

The Best Climbing Trips in Japan

ALPINE CLIMBING JAPAN

アルパインクライミング

ジャパン

ICE, ALPINE, Mt FUJI & 3000m PEAKS

FIFTEEN YEARS PROVIDING THE BEST ASCENTS IN JAPAN

HIMALAYAN EXPERIENCE BOUGHT TO THE MOUNTAINS OF JAPAN

JAPANESE ALPINISM BOUGHT TO THE WORLD

WALLS, RIDGES, PEAKS & FACES

Hundreds of route options, climbed in excellent alpine style

Mt FUJI CLIMBED PROPERLY

The iconic peak climbed the way we do in the Himalaya

THE BEST ICE NO ONE KNOWS

From easy gullies to international class lines and first ascents

WHO WE ARE.

WORKING CLIMBERS

ALPINE CLIMBING JAPAN IS RUN BY CLIMBERS. WE SPENT THE YEAR IN THE MOST OBSCURE RANGES OF ASIA, CALLING JAPAN HOME BETWEEN TIBET, THE KARAKORAM AND THE GOBI DESERT. WE SEE JAPANESE ALPINISM AS HAVING A UNIQUE CONTRIBUTION TO WORLD CLIMBING, AS PROVEN BY DECADES OF VANGUARD ASCENTS TO THE WORLDS HIGHEST AND HARDEST PEAKS

WE RUN OUR TRIPS IN JAPAN THE SAME WAY WE DO OUR TRIPS IN TIBET AND THE KARAKORAM; COMMITTED, ENERGETIC, AUTHENTIC AND NO BULLS#!T. AS REAL CLIMBERS OURSELVES WE PRESENT REAL CLIMBING.

OUR CLIMBERS. REAL CLIMBING FOR REAL PEOPLE

THE CLIMBERS ON OUR TRIPS COME FROM EVERYWHERE AND CLIMB AT EVERY LEVEL. SOME ARE TRAINING FOR 8000m ASCENTS, SOME WANT TO CLIMB THE COOLEST ICE AROUND, AND OTHERS WANT TO SEE JAPAN IN A WAY THAT TOURISTS NEVER WILL. WE ATTRACT PEOPLE WHO THINK DIFFERENTLY, WHO LOVE MOUNTAINS, AND WHO KNOW THAT CLIMBING SETS THEM APART FROM THE ORDINARY.

HALF OF OUR CLIMBERS HAVE COME BACK FOR MORE, THE OTHER HALF MOVES ON TO BIGGER THINGS TO BE REPLACED BY THOSE JUST BEGINNING. OUR CLIMBERS ARE OUR TEAM AND EACH CONTRIBUTES TO THE TRIP

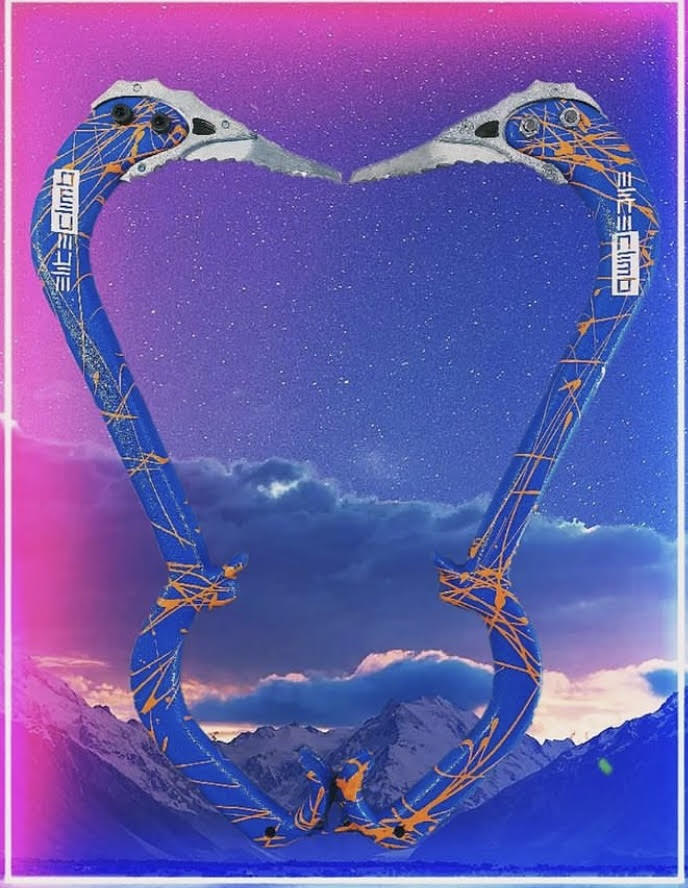

We Use & Recommend

Elite Climb Tools – Parbat Packs – Samaya Tents – Malachowski Down Gear